Types Of Horizontal Stirring Cooking Mixer Machine

Cooking Mixer News /

08/06/2021

Types of Horizontal stirring cooking mixer machine

Horizontal stirring cooking mixer machine classification: Horizontal mixer machine is composed of vacuum type and ordinary type.

Introduction of Horizontal stirring cooking mixer machine: trough-shaped pot body, two-end dish-shaped heads and semi-cylindrical structure, jacket steam heating, worm gear reducer transmission Horizontal stirring, frequency converter speed regulation stirring. The agitator adopts food-grade polytetrafluoroethylene, the agitating blade scrapes the wall and stirs, and there is no dead corner, so that it is evenly stirred. After the material is heated, the hot steam of the steam is quickly emitted.

Technical characteristics of Horizontal stirring cooking mixer machine:

Used for pre-cooking and preparation of high-viscosity food materials, trough-shaped pot body, jacket heating (steam), worm gear reducer driving Horizontal stirring, frequency converter and stepless speed regulation control the stirring speed, the stirrer adopts PTFE pulp , Scraping (rolling materials) mixing, no dead ends, mechanical drive unloading and resetting. It is used for food processing such as bean paste, fruit puree, jam, and high-viscosity materials such as traditional Chinese medicine, and vacuum compression.

Advantages of Horizontal stirring cooking mixer machine:

1. Longze Horizontal cooking mixer machine can use steam heating system or electric heating, which is easy to control the heat source, clean and hygienic, simple and convenient to maintain, and safe to operate.

2. The Horizontal cooking mixer machine is equipped with spiral blade feathers and stirring devices to make the materials flow in circulation and make them fully mixed. At the same time, through the stirring device, the heated material and the unheated material are continuously removed

3. The recycling pipeline is designed as an energy-saving method, which can save energy.

4. The tank body of the Horizontal mixer cooking machine is better designed, which is helpful for the effective flow and utilization of heat in the heating or cooling process.

5. All parts (including the cylinder) of the Horizontal mixer machine are made of 304 stainless steel and other anti-corrosion materials. The blades can be moved (disassembled) for easy cleaning and replacement.

6. The appropriate stirring speed can be selected through the speed control panel.

Horizontal stirring cooking mixer machine classification: Horizontal mixer machine is composed of vacuum type and ordinary type.

Introduction of Horizontal stirring cooking mixer machine: trough-shaped pot body, two-end dish-shaped heads and semi-cylindrical structure, jacket steam heating, worm gear reducer transmission Horizontal stirring, frequency converter speed regulation stirring. The agitator adopts food-grade polytetrafluoroethylene, the agitating blade scrapes the wall and stirs, and there is no dead corner, so that it is evenly stirred. After the material is heated, the hot steam of the steam is quickly emitted.

Technical characteristics of Horizontal stirring cooking mixer machine:

Used for pre-cooking and preparation of high-viscosity food materials, trough-shaped pot body, jacket heating (steam), worm gear reducer driving Horizontal stirring, frequency converter and stepless speed regulation control the stirring speed, the stirrer adopts PTFE pulp , Scraping (rolling materials) mixing, no dead ends, mechanical drive unloading and resetting. It is used for food processing such as bean paste, fruit puree, jam, and high-viscosity materials such as traditional Chinese medicine, and vacuum compression.

Advantages of Horizontal stirring cooking mixer machine:

1. Longze Horizontal cooking mixer machine can use steam heating system or electric heating, which is easy to control the heat source, clean and hygienic, simple and convenient to maintain, and safe to operate.

2. The Horizontal cooking mixer machine is equipped with spiral blade feathers and stirring devices to make the materials flow in circulation and make them fully mixed. At the same time, through the stirring device, the heated material and the unheated material are continuously removed

3. The recycling pipeline is designed as an energy-saving method, which can save energy.

4. The tank body of the Horizontal mixer cooking machine is better designed, which is helpful for the effective flow and utilization of heat in the heating or cooling process.

5. All parts (including the cylinder) of the Horizontal mixer machine are made of 304 stainless steel and other anti-corrosion materials. The blades can be moved (disassembled) for easy cleaning and replacement.

6. The appropriate stirring speed can be selected through the speed control panel.

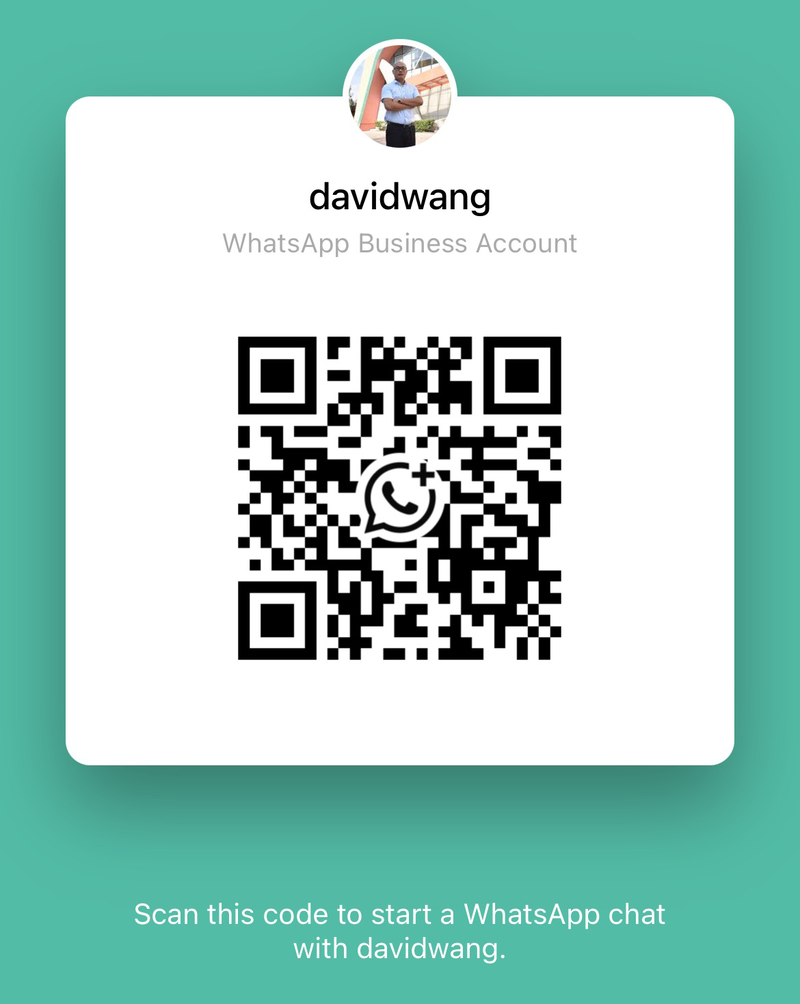

Contact Us:

Shandong Longze Machinery Co.,Ltd

Company website:http://www.cnfdo.com

WhatsApp/Wechat:+86 15253660692

Tel:+86 15253660692

E-mail:395793790@qq.com

Address:Zhucheng Economic Development Zone, Shandong Province, the first five lines west

Contact:Ms. Rena

If you have any question you can contact me ,i can give you the lowest discount.